SKILLS

Below are some of my best skills mentioned what i daily use as Engineer

Mixer |

|---|

Schetsen2.jpg |

Soap-roller |

|

Soap-dispensers |

Mixer-2 |

Unrealistic-Mobiles |

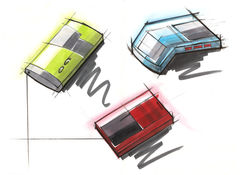

SKETCHING

Sketching is a good way to put ideas / concepts on paper or drafting the image a customer wants. Sketches can be used as visualization to your team, customer or used in presentations for clients. For every different purpose you can use different styles of sketches as visualization. Adding colors in sketches makes it a more realistic visual.

3D MODELLING

I am pretty good at 3D modelling. I mainly work with SolidWorks and I have not encountered an assignment yet that I could not draw in SolidWorks. However, I am open to experiment with other methods and ready to face new challenges. Furthermore, I have some experiences with Unigraphics (Siemens) NX, Rhino 3D and Pro-Engineer.

For visualization in presentations I often use a final Render of the 3D product model, since ‘a good image will tell more than 1000 words’.

Momo_1.JPG |

|---|

Laptop.JPG |

Miffy-Nightlamp.jpg |

momo_projector.jpg |

momo_projector_night.jpg |

Medicijn dispenser.jpg |

Readinglight.jpg |

Clamp.jpg |

Medicine_dispencer_test |

|---|

Clamp_proto |

Proof_of_principles.jpg |

Vercoma_Attraction |

Cutting_mech. |

PROTOTYPING

I don't mind using my hand, I regularly go to a workshop and build visual models or proof of principles.

-Visual models to give a good impression of dimension and feel during a presentation

-Proof of principles can reduce lots of bugs and costs before a product goes to final production.

On the leftt are some photos taken from prototyping.

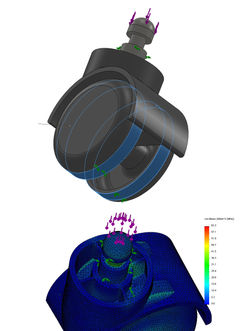

ENGINEERING

While drawing concepts in SolidWorks I also pay attention to what the possibilities are for production. Choosing the right materials is very important for production and final costs.

I have average knowledge of materials like steel, aluminum and plastics and the process possibilities for production.

Some projects I have worked on also included calculating strength and stiffness for using fewer materials, or visualizing if a product will hold under certain circumstances.

Engineering |

|---|

|

Strength_Calculation |

Strength_Calculation |

Piping |

|---|

Assembly |

Stitching |

Foam-cutting |

QUALITY CHECKS

For quality checks I have made several trips to factories in Europa and China. These were good learning experiences.

On these trips I have learned how to check product for faults like dimensions, tolerances, finish, material quality, and firmness etc.